Memmert m360 Cooled Vacuum Oven, VO29cool 29L

Enquire for Price

- Enables precise vacuum drying from +5 °C to +90 °C for sensitive materials

- Integrated Peltier cooling system for efficient, low-temperature operation

- Digital pressure control (5–1100 mbar) with speed-controlled pump management

- TwinDISPLAY control with intuitive TFT interface and programmable AtmoCONTROL software

- AutoSAFETY system with dual over- and under-temperature protection

- Compact 29 L stainless steel chamber with full-view safety glass door

- Certified calibration and energy-efficient design for reliable performance

Optional accessories and technical ventilation are available and purchased separately. If you should require a customised special solution, please contact our technical specialists using our enquiry form or at sales@lasec.com.

Installation is required. Special delivery requirements, such as the need for tail-lift trucks and additional labour and installation for large equipment and hazardous material (Hazmat) packaging, will attract additional freight charges (quoted separately).

Optional accessories are available for purchase separately. If you require a customised solution, please contact our technical specialists by selecting the "Add to enquiry" button and using our enquiry form or at sales@lasec.com.

Installation, training and special delivery requirements, such as the need for tail-lift trucks and additional labour and installation for large equipment and hazardous material (Hazmat) packaging, are chargeable in addition to standard freight and will be quoted separately before dispatch.

Online ordering is currently limited to South African customers, but our full range is still available. If you are ordering from outside South Africa, please log an enquiry or email internationallabsales@lasec.com, and our international sales team will gladly assist you through our traditional sales channels.

Availability:On Request

SKU

VO29cool

BrandMemmert

Product Overview

The Memmert VOcool cooled vacuum oven redefines vacuum drying by enabling gentle, precise drying of temperature-sensitive materials at temperatures below ambient. Powered by advanced Peltier cooling technology, the VOcool provides controlled drying from +5°C to +90°C, making it ideal for applications in pharmaceutical research, electronics, aerospace testing, and sensitive material testing.

With intuitive TwinDISPLAY touchscreen control, users benefit from easy operation, precise vacuum regulation (from 5 to 1100 mbar), and complete process visibility. The robust stainless steel interior (ASTM 316 L) ensures hygienic conditions and easy cleaning, while the fully transparent safety glass door provides maximum visibility and safety during operation.

Available in three chamber volumes, 29L, 49L, and 101L, the VOcool supports a range of lab needs from small-scale experimentation to industrial drying processes. The unit also simulates conditions like those found in an airplane cabin, making it uniquely suited for air freight packaging testing.

Key Features & Benefits

- Gentle vacuum drying at low temperatures – Perfect for temperature-sensitive materials

- Precise vacuum control from 5 to 1100 mbar

- Temperature range: +5°C to +90°C with 0.1°C setpoint accuracy

- Energy-efficient with low power consumption (500–750 W, depending on model)

- Intuitive operation via TwinDISPLAY colour touchscreen

- Peltier cooling technology ensures stability and minimal temperature overshoot

- Stainless steel interior (ASTM 316 L) – corrosion-resistant and hygienic

- Vacuum-tight glass door with safety features for enhanced visibility and safety

- Ideal for packaging tests simulating aircraft cabin pressure conditions

- ATEX-independent solution for laboratories requiring safe vacuum drying

- Three sizes available: 29 L, 49 L, and 101 L

| Temperature | |

|---|---|

| Working temperature range | from 5°C (at least 20 below ambient temperature) to +90°C |

| Setting accuracy temperature | up to 99.9 °C: 0.1 / from 100 °C: 0.5 |

| Temperature sensor | temperature measured through 4-wire Pt100 sensor individually for each thermoshelf |

| Setting temperature range | from +5°C up to +90°C |

| resolution of display for actual values | 0.1°C |

| resolution of display for setpoint values | 0.1°C |

| Pressure (Vacuum) | |

| Vacuum range | 5 to 1100 mbar |

| Pressure control | Digital electronic pressure control for a speed-controlled vacuum pump. Tubing for vacuum, air and inert gas are made of material 1.4571 (ASTM 316 Ti). Programmable, digitally controlled inlet for air. |

| Permitted final vacuum | 0.01 mbar |

| Maximum leakage rate | 0.01 bar/h |

| Pump control | speed control, optimised rinsing procedures for the pump membranes as well as signal output for pump ON/OFF |

| Connection | Vacuum connection with small flange DN16, and gas inlet with fresh air supply |

| Control technology | |

| Calibrate | Three freely selectable temperature values and three freely selectable pressure values |

| adjustable parameters | temperature (Celsius or Fahrenheit), pressure (vacuum), programme time, time zones, summertime/wintertime |

| Language setting | German, English, Spanish, French, Polish, Czech, Hungarian, Italian, Chinese |

| ControlCOCKPIT | TwinDISPLAY. Adaptive multifunctional digital PID-microprocessor controller with 2 high-definition TFT-colour displays. |

| Timer | Digital backwards counter with target time setting, adjustable from 1 minute to 99 days |

| Function SetpointWAIT | the process time does not start until the set temperature is reached |

| Communication | |

| Documentation | programme stored in case of power failure |

| Programming | AtmoCONTROL software on a USB stick for programming, managing and transferring programmes via Ethernet interface or USB port |

| Safety | |

| Temperature control | mechanical temperature limiter TB, protection class 1 according to DIN 12880 to switch off the heating approx. 10°C above nominal temperature |

| AutoSAFETY | additionally integrated over- and undertemperature protection “ASF”, automatically following the setpoint value at a preset tolerance range, alarm in case of over- or undertemperature, heating is switched off in case of overtemperature, compressor in case of undertemperature |

| Autodiagnostic system | integral fault diagnostics for temperature control |

| Alarm | visual and acoustic |

| Heating concept | |

| Heating Concept | Connection for a thermoshelf in the rear panel |

| VO cooling | Peltier cooling unit ensures a surface temperature distribution with a maximum deviation of ±1 K across the entire temperature range |

| Standard equipment | |

| Number of slide-in units | 1 |

| Works calibration certificate | for +10°C/20 mbar |

| Door | full-sight glass door, inside spring-loaded, 15 mm thick glazed panel in safety glass, outside with anti-splitter screen |

| Internals | Cooling- and heating-combination of aluminium, material 3.3547 (ASTM B209), with integrated cooling circuit as well as large-area heating including local temperature sensing (Pt100, 4-wire-circuit); individual overtemperature protection. Further data see stainless steel interior. |

| Stainless steel interior | |

| Material | Hermetically welded stainless steel interior of extremely corrosion-resistant stainless steel, material 1.4404 |

| Volume | 29 l |

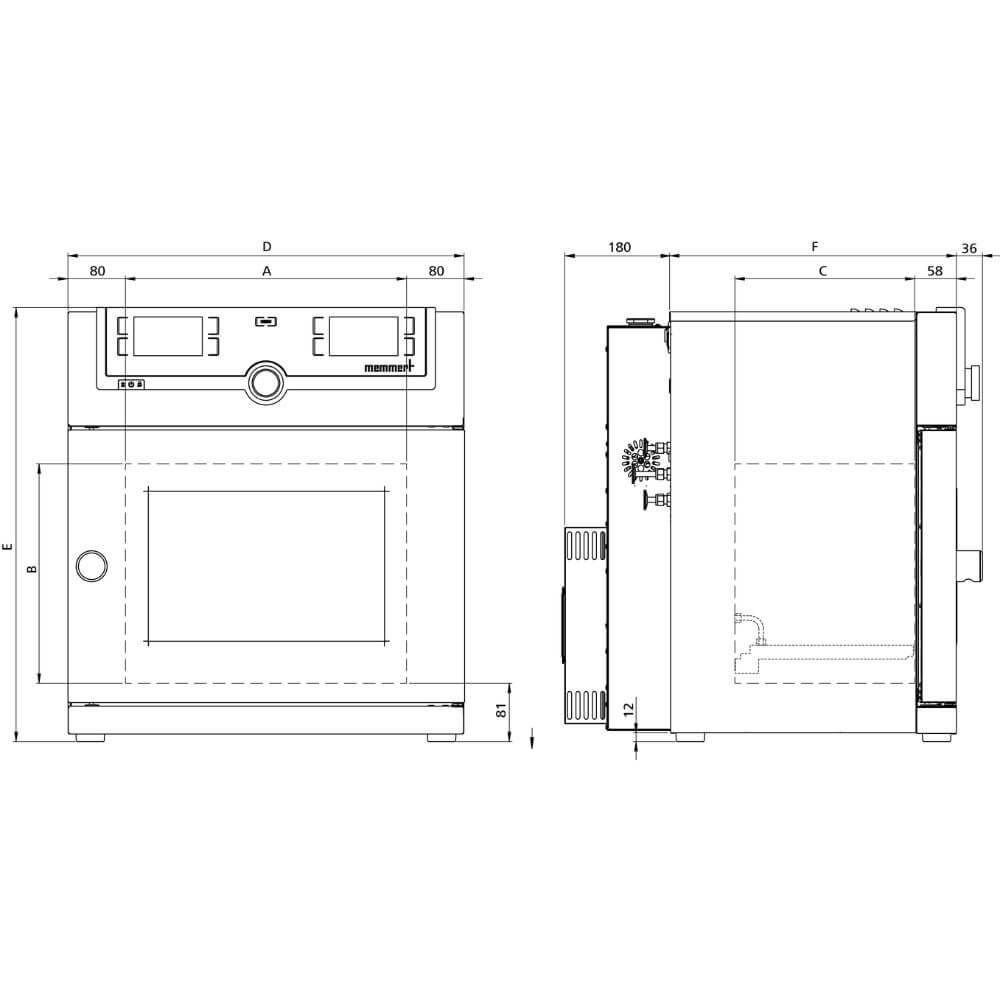

| Dimensions | w(A) x h(B) x d(C): 385 x 305 x 250 mm |

| Max. number of internals | 1 |

| Max. loading of chamber | 40 kg |

| Max. loading per internal | 20 kg |

| Textured stainless steel casing | |

| Installation | 4 adjustable appliance feet |

| Dimensions | w(D) x h(E) x d(F): 550 x 607 x 400 mm (+ 38mm door handle) |

| Electrical data | |

| Voltage | 230 V, 50/60 Hz |

| Electrical load | approx. 500 W |

| Ambient conditions | |

| Altitude of installation | max. 2,000 m above sea level |

| Ambient temperature | +5 °C to +40 °C |

| Set Up | The distance between the wall and the rear of the chamber must be at least 15 cm. The clearance from the ceiling must not be less than 20 cm and the side clearance from the wall must not be less than 8 cm. |

| Humidity rh | max. 80 %, non-condensing |

| Overvoltage category | II |

| Pollution degree | 2 |

| Packing/shipping data | |

| Transport information | The appliances must be transported upright |

| Customs tariff number | 8419 8998 |

| Country of origin | Federal Republic of Germany |

| WEEE-Reg.-No. | DE 66812464 |

| Dimensions approx incl. carton | w x h x d: 660 x 870 x 590 mm |

| Net weight | approx. 66 kg |

| Gross weight carton | approx. 87 kg |

| Brand | Memmert |

|---|

Write Your Own Review