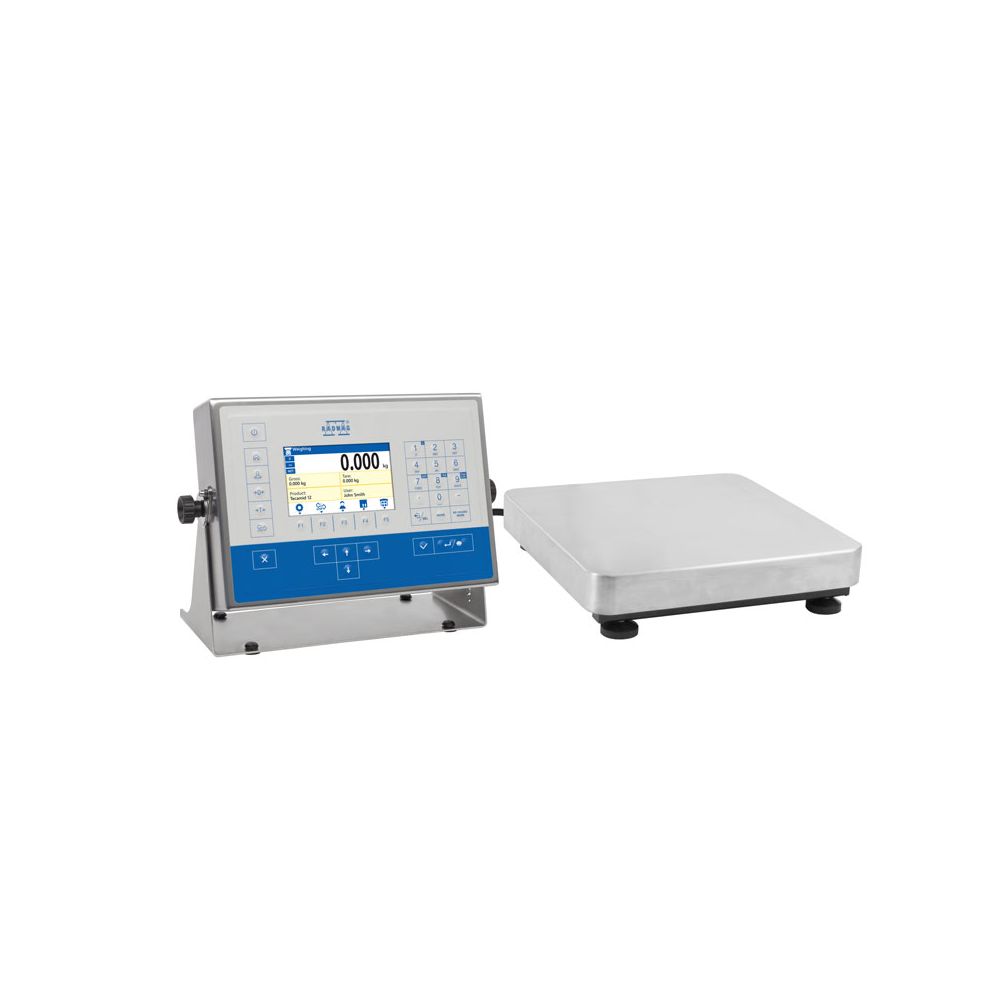

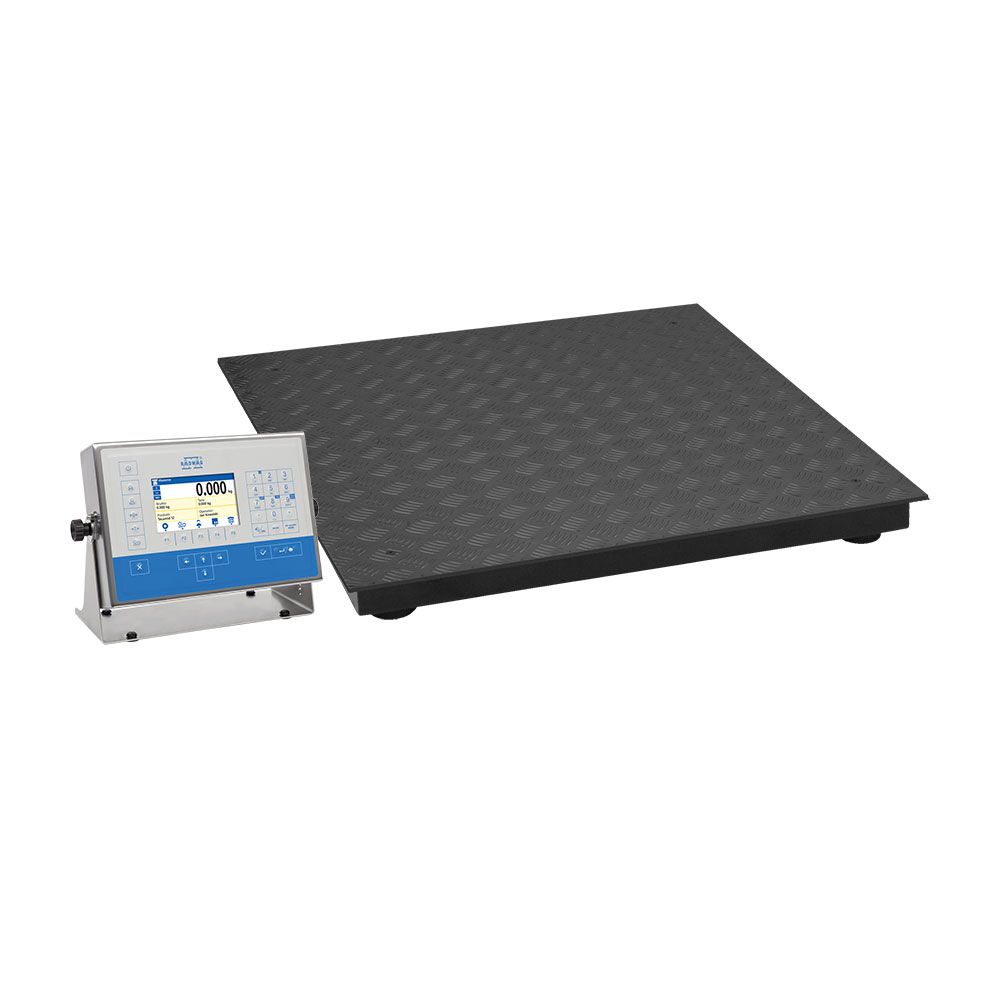

H315.150.H5.M Waterproof Industrial Scale

Enquire for Price

-

Maximum capacity [Max]: 150 kg

-

Readability [d]: 50 g

-

Weighing pan dimensions: 600×600 mm

-

The LCD display is available either mounted on a post or as a detachable unit.

Optional accessories are available for purchase separately. If you require a customised solution, please contact our technical specialists by selecting the "Add to enquiry" button and using our enquiry form or at sales@lasec.com.

Installation, training and special delivery requirements, such as the need for tail-lift trucks and additional labour and installation for large equipment and hazardous material (Hazmat) packaging, are chargeable in addition to standard freight and will be quoted separately before dispatch.

Online ordering is currently limited to South African customers, but our full range is still available. If you are ordering from outside South Africa, please log an enquiry or email internationallabsales@lasec.com, and our international sales team will gladly assist you through our traditional sales channels.

Availability:On Request

SKU

IRDZWP-124-0047

BrandRADWAG

The H315 waterproof industrial scale is engineered for operation in environments with high humidity levels and direct water exposure. This waterproof industrial scale is crafted for precise measurements, essential for scenarios demanding high weighing accuracy.

The Durability of Stainless Steel

Constructed from stainless steel, this balance ensures durability and a prolonged lifespan, effectively withstanding moisture and accidental splashes. Its robust and durable design accommodates the weighing of large items, including pallets of goods. Additionally, the platform's stability against vibration is crucial for accurate measurements of large objects.

More than just Basic Weighing

The H315 waterproof industrial scale goes beyond mere weighing; it integrates parts counting, percentage weighing, animal weighing, and peak hold functionalities. Its versatile modes are designed for those who need quick and consistent weight measurements, even in challenging conditions.

LCD Display

The LCD has proven its reliability over time. It offers clear readings from multiple viewing angles and operates efficiently, making it a key component in RADWAG's technology suite.

Battery-Operated Convenience

In situations where mains power is unavailable or in the event of a power outage, the H315 waterproof industrial scale offers a practical solution. It features an internal rechargeable battery capable of powering the device for up to 7 hours without the need for a mains connection. An optional battery power supply is offered for those requiring extended use, available for an additional fee. The waterproof industrial scale comes standard with an RS232 cable, facilitating compatibility with a wide range of accessories.

Functions

Plus/Minus Control: The control of a sample's mass is conducted by adhering to predetermined minimum and maximum threshold values. The mass is deemed accurate if it falls within these specified limits. The outcome of the weighing process is presented through a bar graph for clear visualisation.

Percent Weighing: The Percent Weighing function facilitates the comparison of measured products against a mass standard. The mass of the standard can either be sourced from a database or determined through direct measurement. In this process, each product's mass is compared to that of the mass standard, which is considered the benchmark, representing an ideal mass of 100%. Consequently, products that weigh less than the mass standard yield results below 100%, while those exceeding the mass standard show results that surpass this threshold.

Totalising: Totalising involves adding a new mass value to an already-obtained one. This process enables the determination of the mass content of a mixture composed of several different components. The totalising operation is constrained by a maximum capacity parameter.

Parts Counting: The parts counting process utilises mass measurement to accurately determine the quantity of items. This process necessitates knowing the mass of a single item, which can be either estimated through measurement or sourced from a database. The core algorithm for counting items involves dividing the total mass of all items by the mass of a single item to ascertain the quantity.

To enhance accuracy, the process incorporates an Automatic Correction of Accuracy mechanism. This feature dynamically adjusts the mass of a single item during the process, effectively mitigating errors that may arise from variations in the mass of similar items.

In industrial applications, part counting can be integrated with check-weighing and dosing operations, providing comprehensive solutions. These systems often include audio signals to notify operators when a predetermined number of items have been weighed. Moreover, it is feasible to employ weighing systems that utilise multiple platforms with varying maximum capacities and accuracies to suit diverse needs.

Internal Battery: The device is equipped with an internal, rechargeable SLA 6 V (sealed lead acid) battery, allowing it to operate independently of a power connection for up to 9 hours. The weighing instrument monitors the battery's status and visually indicates its condition through a specific icon displayed on the screen.

Peak Hold: This feature records the highest transient reading observed during the weighing process. It is commonly utilised in medical scales to retain the weight measurement.

Animal Weighing: This process involves determining the mass of a product that may move unpredictably on the weighing pan. Consequently, this method of mass determination often takes longer than standard weighing procedures. The duration required to accurately measure the product's mass is determined by the user. This allows for adjustments to be made based on the specific characteristics of the product being weighed, ensuring precise and reliable results.

| Metrological parameters | |

|---|---|

| Maximum capacity [Max] | 150 kg |

| Minimum load | 1 kg |

| Readability [d] | 50 g |

| Tare range | -150 kg |

| Max readability for non-verified scale | 5 g |

| OIML Class | III |

| Physical parameters | |

| Display | LCD (backlit) |

| Weighing pan dimensions | 600×600 mm |

| Packaging dimensions | 29.5 kg |

| Gross weight | 26 kg |

| Construction | |

| Protection class | IP 67 construction, IP 68 (1h max)/69 indicator |

| Communication interface | |

| USB Interface | 1 |

| RS232 Interface | 1 |

| Optional interfaces | RS232 or RS485 or 4IN/4OUT or Ethernet or analog output 4-20 mA |

| Electrical parameters | |

| Power supply | 100 – 240 V AC 50/60 Hz |

| Optional power supply | internal rechargeable battery |

| Operation time on batteries | max 7h |

| Environmental conditions | |

| Operating temperature | -10 — +40 °C |

| Relative humidity | 10% — 85% RH no condensation |

| Brand | RADWAG |

|---|

Write Your Own Review