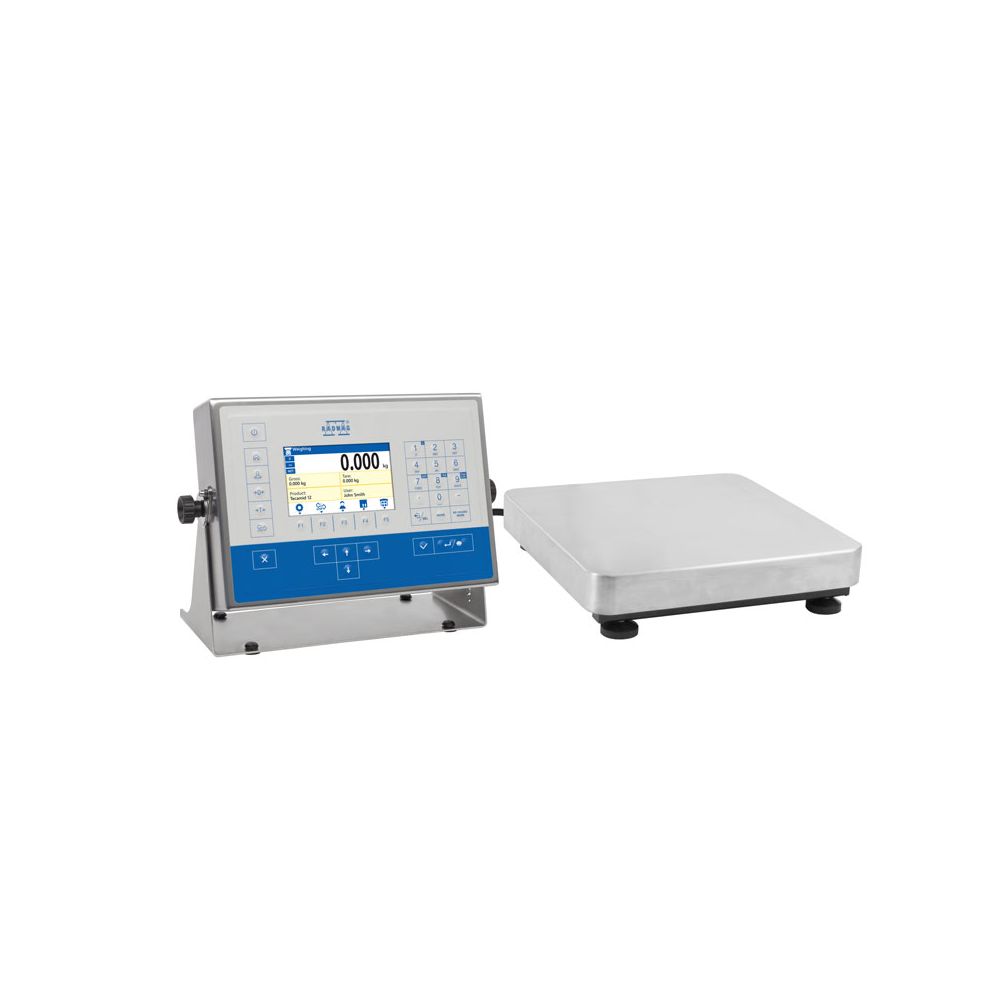

HX5.EX-1.300.H6 One Load Cell Platform Scale

Enquire for Price

- Functions: Labelling, Plus/Minus Control, Percent Weighing, Parts Counting, Statistics, GLP Procedures, Replaceable Unit, ALIBI Memory

- Zones: Certified for hazardous areas (zones 1/21 and 2/22)

- Interfaces: 2 x RS232, 1 x RS485 (intrinsically safe); optional: Ethernet, USB, Profibus DP, analog outputs (4-20mA/0-10V), and additional I/O via IM01.EX module

- Display: Large colour display with customizable widgets and a colour bar graph

- Power Supply: EX-1 for ATEX areas, PM01.EX-2 for non-ATEX areas (ordered separately)

- Compliance: ATEX directive compliant for hazardous environments

- Applications: Suitable for parts counting, checkweighing, statistical analysis, and process control

- Accessories: Optional accessories are available and purchased separately

Optional accessories are available for purchase separately. If you require a customised solution, please contact our technical specialists by selecting the "Add to enquiry" button and using our enquiry form or at sales@lasec.com.

Installation, training and special delivery requirements, such as the need for tail-lift trucks and additional labour and installation for large equipment and hazardous material (Hazmat) packaging, are chargeable in addition to standard freight and will be quoted separately before dispatch.

Online ordering is currently limited to South African customers, but our full range is still available. If you are ordering from outside South Africa, please log an enquiry or email internationallabsales@lasec.com, and our international sales team will gladly assist you through our traditional sales channels.

Availability:On Request

SKU

IRDWWW-006-0044

BrandRADWAG

The HX5.EX scale is a modern weighing instrument that assures fast and reliable measurement in hazardous areas classified as zones 1/21 and 2/22. High-quality electronic components ensure precision and excellent measurement repeatability.

The weighing platforms offered in a wide range of dimensions and maximum capacities, combined with excellent metrological parameters, enable easy selection of an instrument that meets the most demanding requirements.

The standard version of the scale is equipped with 2 serial, intrinsically safe RS232 communication interfaces and one RS485 interface. They facilitate cooperation with equipment intended for operation in hazardous areas. The possibility to add digital inputs/outputs extends the range of instruments compatible with the indicator by automatic elements compliant with the ATEX directive.

More demanding customers can use the IM01.EX module, installed in the safe area, which extends the available connectors by Ethernet, USB, 4-20mA/0- 10V analogue outputs, Profibus DP, and additional digital inputs/outputs. This enables cooperation with external devices: barcode scanners, printers, external displays, control buttons, light signalling towers, other controlling/signalling devices, systems for automatic process control, and superior IT systems.

Scale operation requires the use of a dedicated PM01.EX power supply, which is not a standard scale component.

To operate the scale, order a selected type of dedicated, intrinsically safe power supply.

Power supply types:

- PM01.EX-1: power supply for operation in the ATEX area. Used when it is required to connect the power supply to a voltage source placed in a hazardous area.

- PM01.EX-2: power supply for operation outside ATEX area. Used when a power supply connection to the voltage source is carried out outside a hazardous area.

Complex software enables the performance of many tasks related to mass measurement, such as parts counting, check weighing, and statistics.

The scales feature a user-friendly graphic interface, which can be customized using widgets. This and the large colour display of high-resolution guarantee the easy and clear transmission of data on the current process.

The colour bar graph significantly influences performance by signalling whether the weighing result is within declared thresholds or not.

| Metrological parameters | |

|---|---|

| Maximum capacity [Max] | 300 kg |

| Minimum load | 2 kg |

| Readability [d] | 100 g |

| Tare range | -300 kg |

| OIML Class | III |

| Physical parameters | |

| Display | 5" graphic colour |

| Cable length | 2.5 m |

| Weighing pan dimensions | 800×800 mm |

| Packaging dimensions | 820×1250×490 mm |

| Net weight | 46.8 kg |

| Gross weight | 53 kg |

| Construction | |

| Protection class | IP 66 / 67 construction, IP 66 / 68 terminal |

| ATEX Certification | II 2G Ex ib IIB T4 Gb |

| IECEx Certification | Ex ib IIB T4 Gb |

| Construction | Stainless steel AISI304 |

| Weighing pan material | Stainless steel AISI304 |

| Communication interface | |

| Communication interface | 2×RS232, RS485 |

| Electrical parameters | |

| Power supply | 100 - 240 V AC 50/60 Hz |

| Power consumption max. | 15 W |

| Environmental conditions | |

| Operating temperature | -10 - +40 °C |

| Relative humidity | 10% – 85% RH no condensation |

| Indicator | PUE HX5.EX-1 |

| Brand | RADWAG |

|---|

Write Your Own Review