VACUU·PURE 10 Screw Pump

Enquire for Price

- Model: VACUU·PURE 10 Screw Pump

- For non-corrosive applications

- 10-3 mbar vacuum range

- 100% oil-free

- No abrasion

- No wear parts

- Ultimate vacuum: 5 x 10-3 mbar

- Max. pumping speed 50 Hz: 10 m3/h

Optional accessories are available for purchase separately. If you require a customised solution, please contact our technical specialists by selecting the "Add to enquiry" button and using our enquiry form or at sales@lasec.com.

Installation, training and special delivery requirements, such as the need for tail-lift trucks and additional labour and installation for large equipment and hazardous material (Hazmat) packaging, are chargeable in addition to standard freight and will be quoted separately before dispatch.

Online ordering is currently limited to South African customers, but our full range is still available. If you are ordering from outside South Africa, please log an enquiry or email internationallabsales@lasec.com, and our international sales team will gladly assist you through our traditional sales channels.

Availability:On Request

SKU

IVAC20750000

BrandVACUUBRAND

The dry screw pump VACUU·PURE 10 vacuum pump reliably delivers the benefits of oil-free vacuum technology in the pressure range down to 10-3 mbar. VACUU·PURE 10 vacuum pump combines three important benefits for the user: 100% oil-free, no abrasion, and no wear parts.

VACUU·PURE 10 vacuum pump is ideal for clean processes which require a dry and hydrocarbon-free vacuum. The spindles of the screw pump run contact-free and are thus free of abrasion and wear. The screw pump is especially designed for processes in the vacuum range down to 10-3 mbar, however, unlike other fine vacuum technologies, it can be used across the entire pressure range, from atmospheric pressure to its ultimate vacuum. The evacuation of even larger systems from atmospheric pressure down to the 10-3 mbar vacuum range can be done without changing the vacuum pump.

VACUU·PURE 10 vacuum pump easily handles high levels of vapour accumulation through its extraordinary condensate compatibility. Thanks to this capability, a gas ballast is unnecessary, avoiding associated disadvantages like the reduction in pumping speed and an increase in noise levels. The integrated regeneration mode enables rapid drying of the pump at the end of the process. This allows sample throughput to be increased significantly as compared to other pump technologies.

Application Examples for the VACUU·PURE 10 Vacuum Pump

- Fore vacuum generation for turbomolecular pumps

- Particle accelerators

- Analytical applications

- Scanning tunneling microscopy

- Mass spectrometry

- Regeneration of cryo pumps

- Coating

- PVD / CVD

- Degassing

- Drying

| Max. pumping speed 50 Hz | 10 m3/h |

| Ultimate vacuum | 5 x 10-3 mbar / 3.8 x 10-3 torr (at 1013 mbar ambient pressure) |

| Vacuum controller | without controller |

| Lower ambient temperature (operation) | 10 °C |

| Upper ambient temperature (operation) | 40 °C |

| Lower ambient temperature (storage) | -10 °C |

| Upper ambient temperature (storage) | 60 °C |

| Max. back pressure (abs.) | 15 mbar above atmospheric pressure bar |

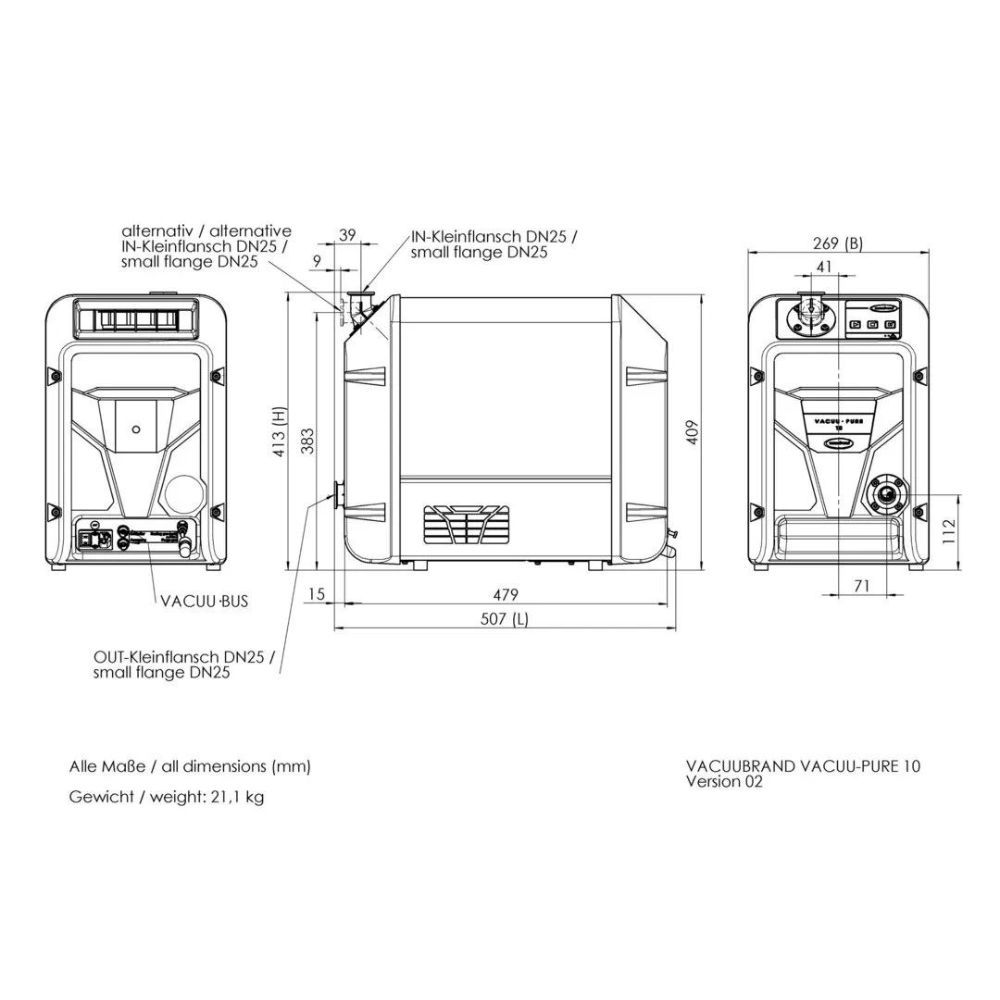

| Inlet connection | small flange KF DN 25 |

| Outlet connection | small flange KF DN 25 |

| Rated motor power | 0.7 kW |

| Protection class IEC 60529 | IP 20 |

| Dimension L in mm | 507 mm |

| Dimension B in mm | 269 mm |

| Dimension H in mm | 413 mm |

| Weight | 21.1 kg |

| Noise (sound pressure level) in dBA at 50 Hz or 1500 rpm/62% (VARIO)/1500 rpm (VARIO-SP)/12500 Upm (VACUU·PURE®) | 52 dBA |

| NRTL certification | Yes |

| Items supplied | Pump completely mounted, ready for use, connection with small flange KF DN 25, with manual. |

| Rated mains voltage range 1 | 100-230 V |

| Mains frequency 1 | 50-60 Hz |

| Interface | VACUU·BUS: Modbus RTU |

| Brand | VACUUBRAND |

|---|

Write Your Own Review