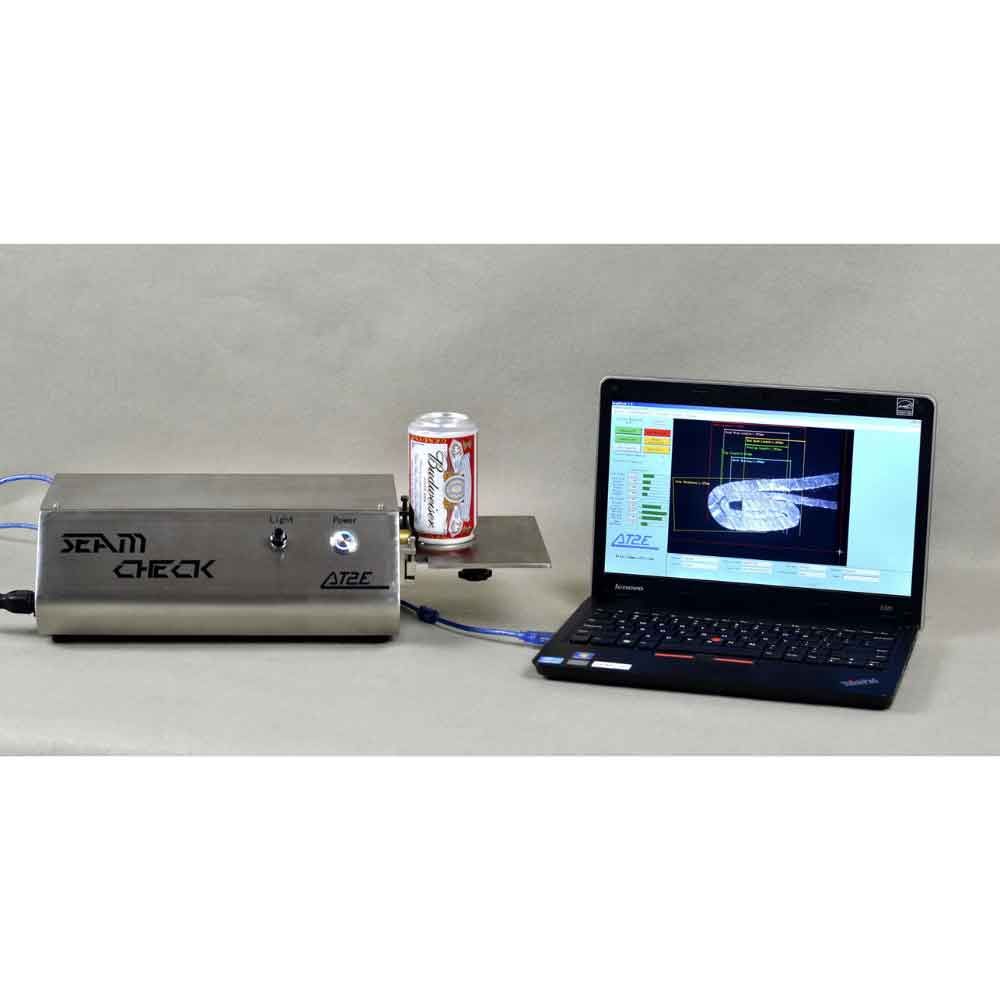

SeamCheck – Automatic Double Seam Projector

Enquire for Price

- Power supply: 115 V/230 V

- Serial interface: RS 232 C

- Resolution: 0,001mm

- Accuracy: 0,005 mm

- Magnification factor: 60 X

- Line positioning magnification factor: 180 X

- Platform capacity: Up to 180 mm dia. can

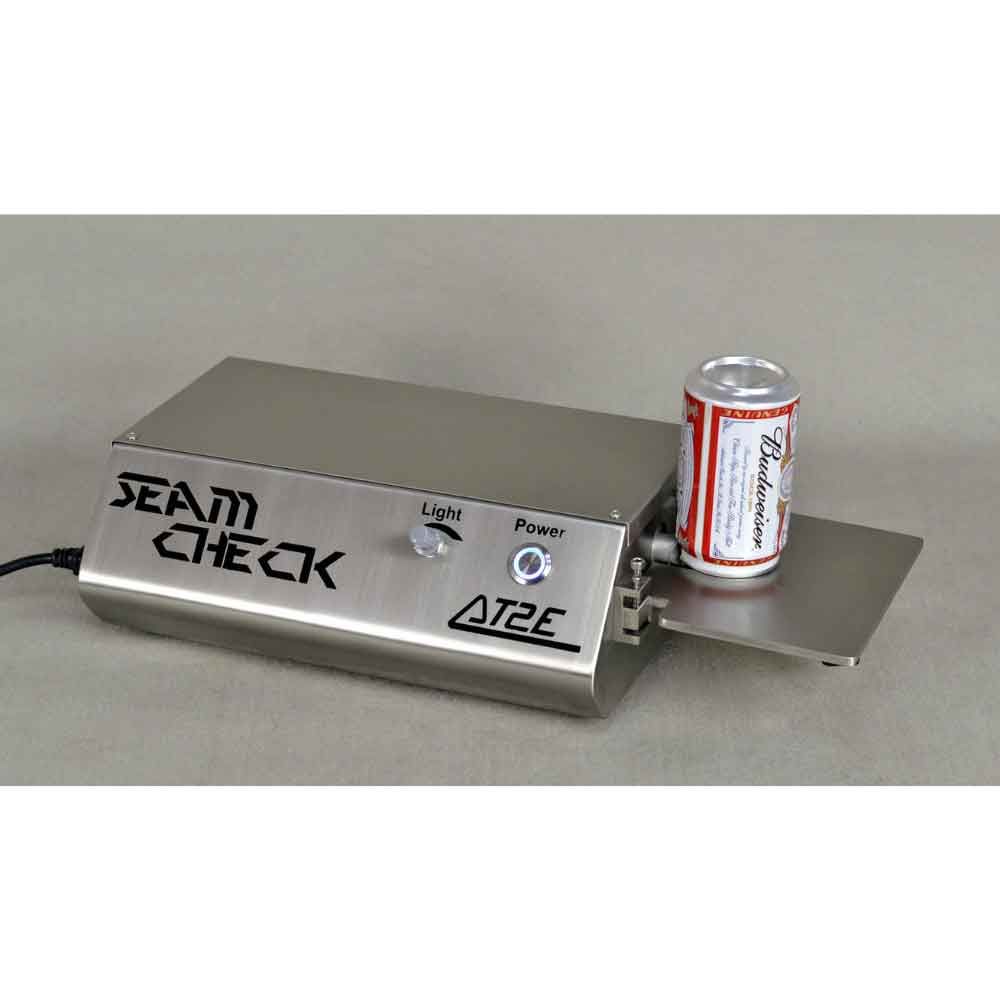

- Dimension: 470 (L) x 200 (W) x 125 (H) mm

- Net weight: 5 kg

- Equipment includes: SeamCheck video seam projector; SeamCheck professional seam measurement software; 2 mm calibration piece

- Installation and Training Services: Please note that this equipment requires professional installation and training by a qualified technician, which may involve additional costs not included in the purchase price.

- Optional accessories are available and can be purchased separately.

- Online ordering is currently limited to South African customers, but our full range is still available. If you are ordering from outside South Africa, please log an enquiry or email internationallabsales@lasec.com, and our international sales team will gladly assist you through our traditional sales channels.

Availability:On Request

SKU

IATESEAMCHECK-FULL

BrandAt2e

Seaming quality is crucial for can inspection and is one of the primary concerns for can, beverage, and food manufacturing companies. The AT2E SeamCheck Automatic Double Seam Projector offers the most convenient method for conducting seam inspections. When used with the AT2E seam saw, one can obtain a clear seam section image. Paired with the professional SeamCheck software, this setup allows for quick and accurate seam measurements.

Features and Benefits

- Quick Measurement: Features automatic line positioning with an auto-measure function, completing measurements in just 1 second.

- Advanced Video Capture: Comes with a high-definition video capture device, ensuring interference-free imaging even in varied external light conditions.

- Database Management: Integrated software with database management capability. Users can save, review, and manage measurement results and images seamlessly.

- Measurement Parameters: Offers 9 standard measuring parameters, including seam length, body hook length, end hook length, overlap, seam gap, overlap rate, body hook lapping rate, end hook lapping rate, and on-screen seam thickness. It can be expanded to 12 parameters with additional gauges, encompassing actual seam thickness, actual countersink, and tightness.

- Compatibility: SPC-compatible and comes with a data adapter for capturing data from the Mitutoyo Digital Indicator. This includes measurements like actual seam thickness, actual countersink, actual can height, and actual flange width.

- Data Export: Easily export all data into an Excel format.

- Customizable Reports: Users have the flexibility to customize the report format, catering to diverse company styles.

- Quality Checks: Predefined qualification standards are available. The system can automatically evaluate and alert users if measurements do not meet these standards.

- Visualization: Measurement results and label lines are displayed directly on the captured image. Results are also mirrored in the respective fields on-screen.

- Graphical Analysis: The graph chart statistic feature aids in the automatic analysis and comparison of measurement data.

- Magnification: An inbuilt magnifier allows users to zoom into the test image, ensuring accurate line positioning.

- On-screen Alerts: Measured values are displayed on-screen with alarms to indicate if values fall outside the specified range.

- Image Storage and Printing: Seam images can be both stored for future reference and printed.

- Calibration: The unit includes a calibration piece, enabling users to recalibrate whenever necessary.

- Adjustable Platform: The platform's height can be adjusted to cater to various testing needs.

- Adjustable Lighting: Ensure optimal image capture with adjustable light settings.

Optional parts

- ANSS – Antinoise Seaming Cutting Saw / SS-1 Seaming Cutting Saw

- STG-1 Seam Thickness Gauge (digital)

- CG-D Countersink Gauge (digital)

- FWG-1 Flange Width Gauge

- HG-1 Height Gauge

- DTB-1 Data transporting Box with cables

| Brand | At2e |

|---|

Write Your Own Review